Inventory overview by Stock Value and Stock Quantity, enable you to keep tab of inventory in each location.

In addition, it displays the current stock and the available forecast quantity so that you are aware of the stock status at a glance

- 01

Inventory overview by Stock Value and Stock Quantity, enable you to keep tab of inventory in each location.

In addition, it displays the current stock and the available forecast quantity so that you are aware of the stock status at a glance

The dashboard displays the Inventory Aging by over a Period of Time or by Location.

You can focus your attention on the slow moving stock and set strategies to clear them, eg Clearance Sales, to free your warehouse space

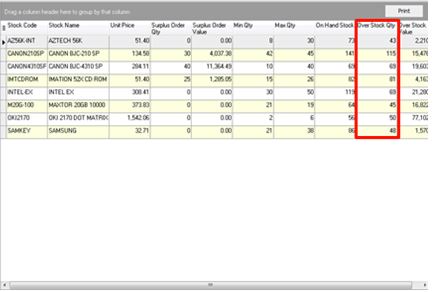

Generate projected excess inventory

shows the Excess Stock by Product for comparison with Maximum, Minimum Stock Level and Quantity on Hand in Purchase Order. Information on Excess Stock by Location can also be generated by Quantity, Stock Value or Item Count parameters.

Inventory control in place to reduce Excess Stock by providing Sales Promotion for Slow moving stocks.

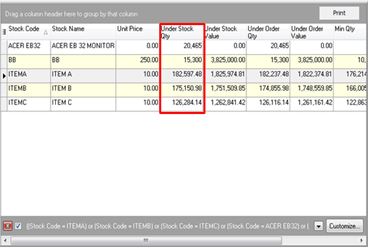

The dashboard shows the Product Shortage. It shows the Quantity on hand, Maximum and Minimum Quantity and the shortfall. Information will indicate if there is sufficient stock quantity on hand to meet the Sales Order.

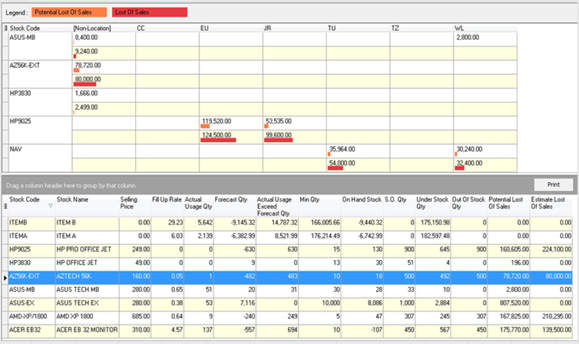

Generate revenue at risk due to shortages by location for each product.

Key indication of Potential Lost of Sales is and Actual Lost of Sales revenue so that you can take preventive measures immediately.

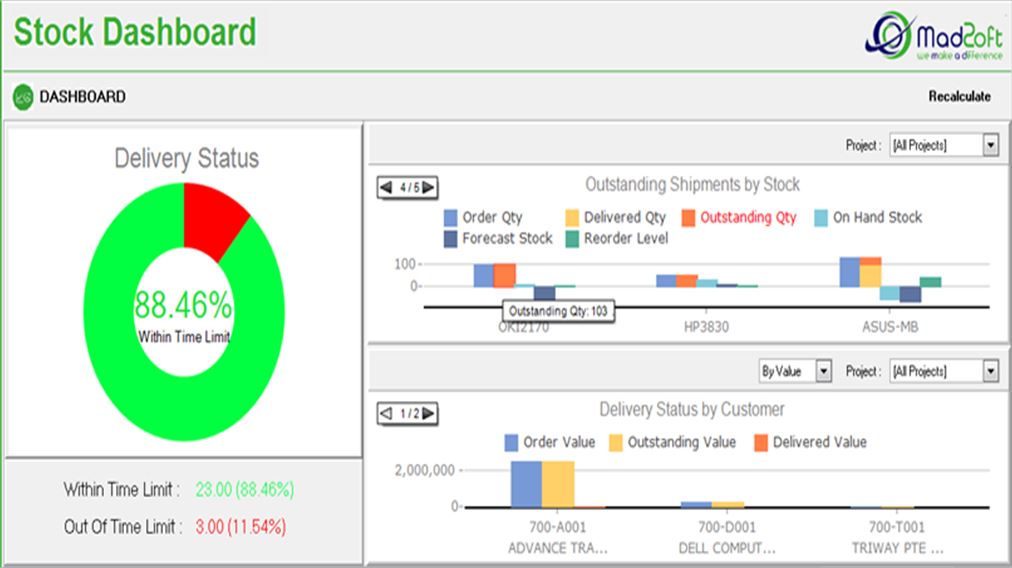

Inventory Dashboard to show the delivery status that have been fulfilled within the time limit and tardiness in delivery. Order quantity, delivered quantity, outstanding quantity, On-hand stock, Forecast stock quantity and Reorder level information facilitate better Inventory planning and control.

Track your stock easily by organizing in the various locations and bins. You can do stock transfer between locations and bins. Good on consignment delivered to retail outlets can be tracked easily.

Stock balance by locations can be generated so you know exactly where they are.

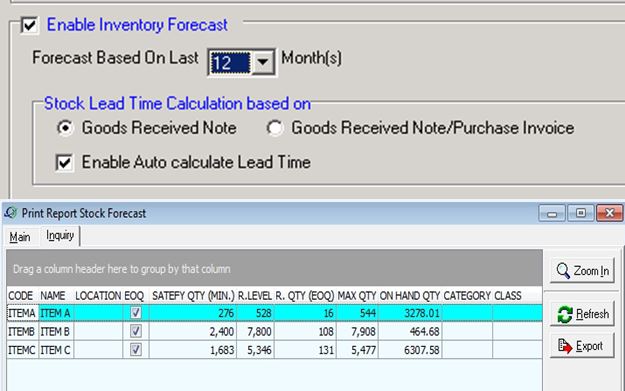

Built-In Tools available to let you set parameters for forecasting eg you can define the lead time based on historical data to calculate forecast.

Forecasting method help calculate Minimum quantity, Reorder level, Maximum Quantity and Reorder Quantity automatically.

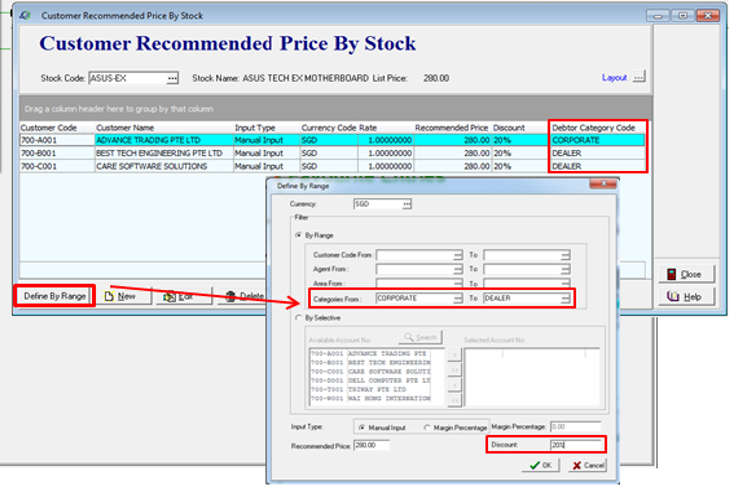

You can set different pricing or discount for your stock items. It can be set by stock range or by customer or supplier category.

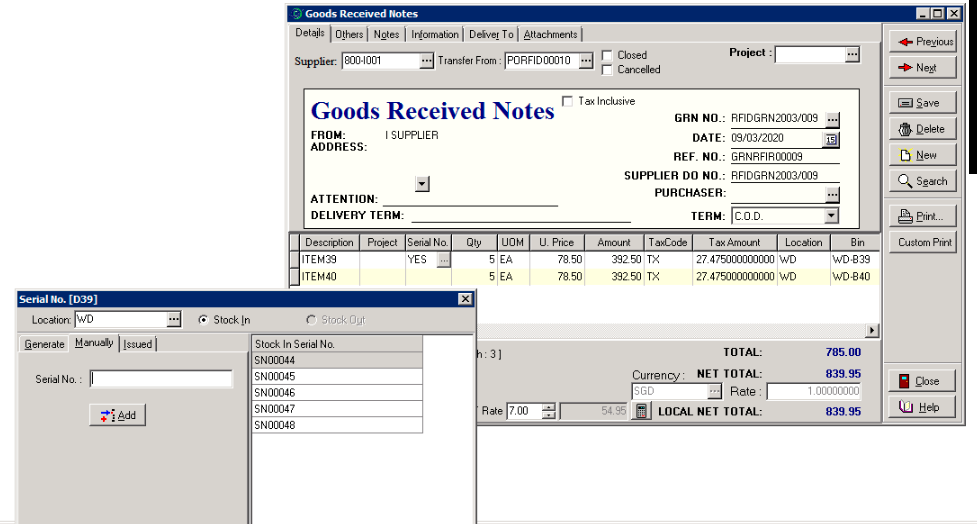

MadSoft RFID relieves keyboard entry to reduce data entries errors, improving accuracy, reduce manpower and cut down processing time.

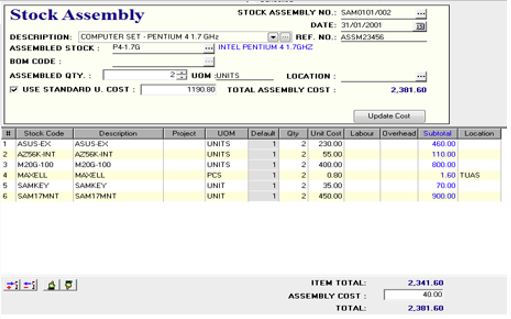

MadSoft allows you to build finished good with different components, parts. You can define multiple sets of Bill of Materials (BOM) for the finished goods if the components are different.

Overhead or labour cost for each component can be input or overall assembly cost included which give rise to a new unit cost of finished cost.

You can easily track the movement of your stock with serial number. The serial number can be generated automatically or manually.

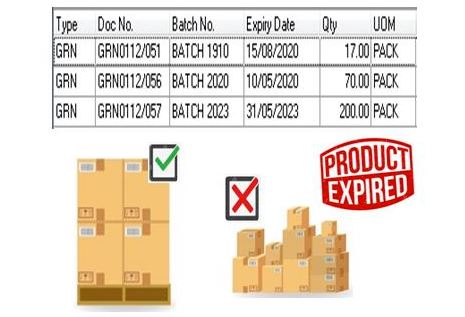

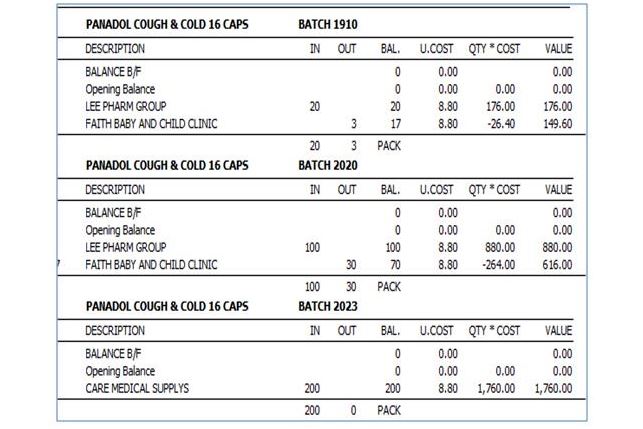

MadSoft allow you to organise your stock by batch and set expiry date.

With the information in the system, we can decide which batch of products to sell first.

Create sales promotion to sell fast for products with short shelf life.

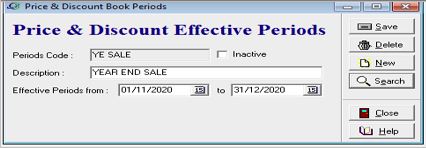

Customers are lured by sales and discounts, especially during seasonal period. Specify the promotional period and set special prices or discounts by stock quantity, stock category or by customer category.

The prices will automatically adjusted during the promotional period.

Promotion period, discounted percentage & pricing are compulsory field in order to enjoy this seasonal sales

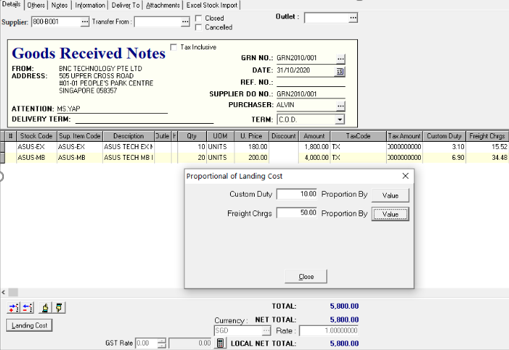

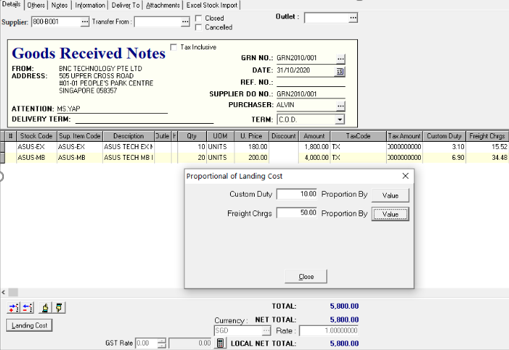

Landing costs such as freight charges, insurance, custom duties, etc are important expenses. They constitute to the cost of goods purchased. MadSoft helps to allocate the landing costs to obtain the final cost of your stock.

Manual calculation or by value is available